Small UK company? £10k grants up to 40% off an LED project available. Click here for more info

call us on +44 (0)1483 688170

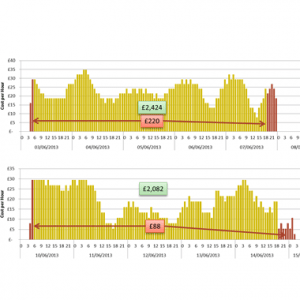

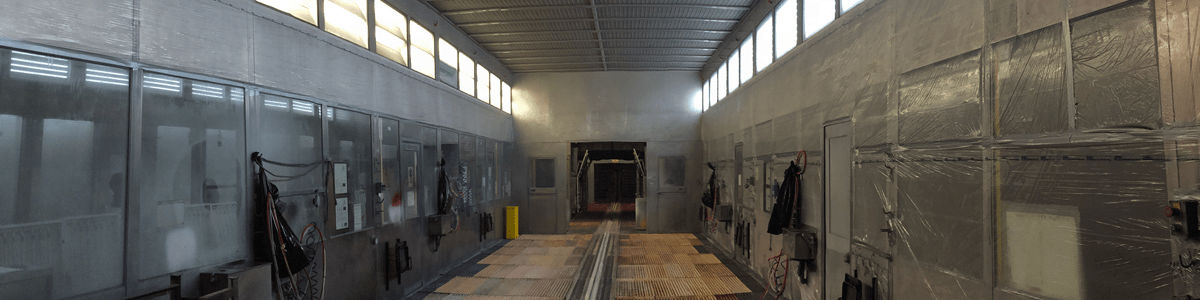

An automotive OEM's paint shop's operational team wanted to undertake a spray booth energy analysis to see if there were opportunities to reduce its energy consumption. Ecopare's Lean Energy Management solution was installed over a four week time frame to gather real-time energy data in the major energy systems including the air handling units, robot lines vs manual spray lines, central water reticulation and lighting systems.

Key activities included:

On the back of the provided information, the client was able to: